MDF Plate Portable UV Curing Machine

TM-UV-100 portable uv curing machine video http://tamprinter.en.made-in-china.com Technical Parameters Product Image 3kw

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | TM-UV-100-2 |

| Operation Pressure | Atmospheric Pressure |

| Operational Method | Continuous |

| Model No. | TM-UV-100-2 |

| Power Supply | 220V |

| UV Lamp Power | 2000W |

| Main Wave Length | 365nm |

| UV Radiation Length | 140mmx400mm |

| UV Lamp Lifetime | 800 Hour |

| UV Case Size | 420mmx410mmx810mm |

| Best Radiation Distance | 75-150mm |

| Total Net Weight | 35kg |

| The Life of The Bulb | 800-1200 Hour |

| Transport Package | Wooden Case |

| Specification | CE |

| Trademark | Tamprinter |

| Origin | China (Mainland) |

| HS Code | 8443192290 |

| Production Capacity | 60 Sets/Month |

Product Description

TM-UV-100 portable uv curing machine videohttp://tamprinter.en.made-in-china.com

Technical Parameters

| Model No. | TM-UV-100-1 | TM-UV-100-2 |

| Power supply | 220V | 220V |

| UV lamp power | 1000w | 2000w |

| Main wave length | 365nm | 365nm |

| UV radiation length | 140mmX400mm | 140mmX400mm |

| UV lamp lifetime | 800 hour | 800 hour |

| UV case size | 490mmX410mmX670mm | 420mmX410mmX810mm |

| Best Radiation distance | 75-150mm | 75-150mm |

| Total Net weight | 25KG | 35KG |

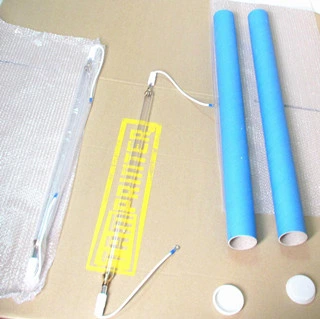

Product Image

3kw Mercury Lamp Dry Pegmentalne Red Colors Need About 8 Sec,black Ink Longest, transparent Uv Varnish Shortest,also Can Use Gallium Lamp

Product name

Portable UV Curing Machine

Item

TM-UV-100-2kw

Details

Portable UV curing machine for UV glue, UV ink, UV test. Application for UV repair, wood floor UV curing, Wall corner UV curing which the big UV machine can not cure.

Features

Small size with light weight,Portable design, one lamp, easy operation. One side and multi-side curing flexible controlling.Special for test(UV ink, UV oil, UV painting, UV coating )Economic style with steady performance.

control system

It is used to control the whole light solid machine work systemplease kindly note

1,Fan control by the best temperature automatic control (see right-hand chart), because there may be omissions control by people, also is not accurate enough.

2,This boot should first turn on the light, 2 to 3 minutes to open the fan (fan is not temperature control, this time for the UV machine had been set before shipment).

3,Should take the fan continues to run after shutdown, until the lamp and body cooling.

4,The second starting to wait until completely cooling tubes starting.

ventilating system

It consists of fan, air duct, the wind mask. Here is that should be paid attention to the choice of fan and air volume control and ventilation.

1,The selection of the fan according to the UV lamp power and the actual situation of housing space. General distribution and convulsions two wind turbines, but I have only small UV machine equipped with a ventilation fan. Fan power is not enough that leads to exhaust air temperature inside the case, lamp life shortened, melt, even also make curing product quality difficult to guarantee; Air volume of fan power if too large, will make the temperature inside the case is too low, the UV lamp can't work at full power, curing is not easy to dry

2,Exhaust way refers to take the lead wind supply air or air supply on the wind, etc. But either way, not the wind blows directly to the UV lamp, because the consequences of doing so is to make the UV lamp for heat loss is too big and not full power work (changed from white to not dazzling light blue), make the ink doesn't dry.

Payment Terms

TT/LC/western union

If you have any question, please contact us!

Related Products